End Grain Cutting board

End Grain Cutting board is a board, wherein the wood grains are perpendicular to the cutting surface, and not parallel as in ordinary cutting boards.

Most professional cooks use End Grain Cutting boards. Why? There are several reasons:

- The end surface of the wood is more firm and long-lived. Hardness of end surface is almost one and half times higher than hardness of side surface. For example, end grain hardness is 622 kgf/cm2; edge grain hardness is 521 kgf/cm2, face grain hardness is 463 kgf/cm2.

-

When you use the End Grain Cutting board, knives stay sharp longer and need to sharpen rarer. Wood grains are perpendicular to a cutting face, and the blade of the knife as it move apart the grains. When you use an edge grain board, a knife just cut through grains, which leads to fast dulling of a knife. It is very important for professional cookers who have to sharpen knives several times every day.

- It is clear when you use a board many times, grains are cut through in several places and tiny piece of wood get in food. That is why all the ordinary boards are noticeably "cut through" in the center. However, a human stomach is not adapted to the digestion of cellulose.

- The End Grain Cutting Board less subject bacterial contamination, because after cutting grains "close" and oil coating protects against bacterial penetration inside the grains. Grains are cut through in an outer board and bacteria get inside the grains without problems. In general, wood boards are more hygienic than plastic or glass.

Let us show you the difference – here we slashed a common board and end grain one using the same knife and putting the same effort. Then we treated the board with oil and got some macro-photos from one and the same distance and shooting angle.

Image 1. Cuts at an oak face grain cutting board

As you see a sharp knife made deep cuts in wood. Wood grains are completely cut up and in later use it will fall.

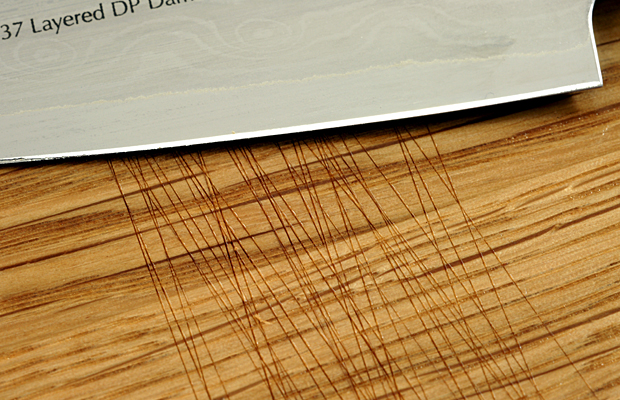

Image 2. Oak end grain cutting board

Cuts are still evident but less distinct because the knife doesn’t cut up grains passing over by them.

Then we treated each board with mineral oil.Image 3. Oak face grain cutting board treated with oil

After oil treating procedure cuts become more distinct than before treating. Cutted grains was oiled that made wood darker.

Image 4. Oak end grain cutting board treated with oil

Here the cuts are almost imperceptible, because in this case a knife doesn’t cut the grains across but make cuts from the end of the grain. It oiled to a few millimeters deep whereas on face and edge grain cutting boards are covered with a thin oilslick that doesn’t permeate the wood. Grain is swelling and closing due to oil treating guarantees board’s hygiene and saves its unique layout.

The boards are made from high quality wood where moisture content is less than 8%. We use mainly hard wood like an oak, an ash, a walnut, a horn beech, a maple, a birch and small amounts of hard African and American wood species like padauk, sapele, makore, mahogany, amaranth, zebrano. We can make Pine End Grain Cutting Boards, but these boards are quite soft (a hardness of pine end surface is 2 times less than harness of oak) and it is better to use it with dry foodstuff like bread, cheese, etc.

The boards are treated by food grade mineral oil to prolong service life, to protect against bacteria and to make beautiful appearance of a board. Mineral oil is tasteless and odorless. We use analog of medical mineral oil – the liquid paraffin intended for ingestion. You can buy it in a pharmacy. Sunflower, olive, and other food grade oils cannot be used for treatment, because after a while they become bitter and will transmit this taste to foodstuff. Linseed oil is the only exception, but even it is worse than mineral oil.

You have to observe items of care of board and if you do it, you board will serve and gladden you.

A price of the board depends on chosen material, sizes of the board and complexity of the pattern.

All of the boards have little feet.

It was made specially. If moisture accidental get under a board without feet (that occurs often), and the board lay few hours in that way, then it will absorb moisture. Then the board will bend on drying, but we do not want it. Besides, the boards are very hard and it is not necessary to use reverse side, because even in a few years you will not be able to significantly cut the front side of a board. The feet can be made of wood, plastic or rubber.

We present here finished models of boards. However, we can manufacture the boards of various patterns and sizes according to your order. For this, you should send e-mail to our support service and write there

- The approximate pattern, taking as any of the analog of boards represented in the photo gallery;

- The shape of a board – rectangular, square, round, oval or ellipse form;

- The sizes of a board – length (from 3.93 to 27,56 inches, from 100 to 700 mm), width (from 3.93 to 17.72 inches, from 100 to 450 mm) and height (from 1.18 to 3.15 inches, from 30 to 80 mm).

- Preferred wood species

- Type of oven fork of a board – splits in the bottom of side face, one hole on the edge, one hole in the corner, the two holes on the edges.

Manufacturing process of a board is quite difficult and labor consuming. It is usually takes 3-4 days to fabricate one board (with the time of drying glue and oil). This process is presented in our story in pictures in more details. Final models you can see in photo gallery.